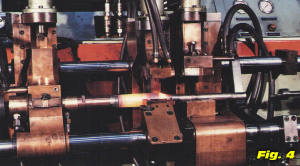

Through the upsetting process, there is the possibility to reducing at minimum the machining allowance, thereby obtaining smooth surfaces that in some instances allow the elimination of subsequent machining.

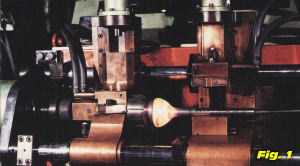

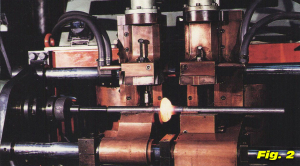

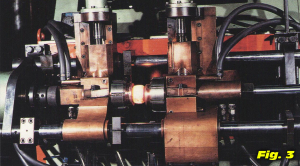

The edge of the bar is heated and preformed quickly, precisely and uniformly, only in respect of the necessary segment (picture 1), thereby decreasing the formation of dregs, with a resultant longer duration of moulds. It is moreover possible to carry out, through simple tuning operations, the heating and upsetting of the bar at any intermediate point (picture 2); heating and total upsetting of the segment to be moulded (picture 3); elongated upsetting of large volumes in moderate mould, thanks to the supplementary central body (picture 4).